Magnetic Stripe Testing

Overview

A magnetic stripe (magstripe) is a band of magnetically modifiable iron-based material. The magstripe is placed on the back of plastic cards and is used to store and communicate data. Magnetic stripe cards are commonly used for credit/debit cards, loyalty/gift cards and identity cards. For financial cards, some international markets are yet to fully adopt EMV or smart cards and use of the Magnetic stripe is often used as a fall-back for worldwide interoperability.The process of Magstripe Encoding modifies the magnetic particles into a bar arrangement which can be read as binary data. When reading the card, the magnetic stripe moves through a magnetic field of the read/write head, generating electric pulses. The spacing of pulses determine whether a '0' or '1' is read.

Testing

Card Testing International checks the quality of your magstripe cards to ensure they can be read reliably. It only takes 1/3mm misplacement of the encoded track location to create problems for the reader.CTI evaluates the placement and quality of the magstripe band against internationally recognised standards, how well a card magstripe \ can be encoded and read based on the various physical characteristics of the magstripe and the card. CTI also can asses an encoding device's ability to accurately encode magstripe cards.

Standards for Magnetic Stripe Cards

-

ISO/IEC 7811-6- Physical Characteristics

- Surface Profile & Roughness

- Magnetic Stripe Roughness

- Magnetic Stripe Positioning

-

Cards must also comply with ISO/IEC 7810 ID Cards - Physical Characteristics

- General Compliance e.g. height, width, thickness etc.

- Durability e.g. Peel Strength, Resistance to Heat/Chemicals etc.

-

Personalisation covered by:

- ISO/IEC 7811-1 Embossing

- ISO/IEC 7811-6 HiCo magstripe encoding

Common Magnetic Stripe Issues

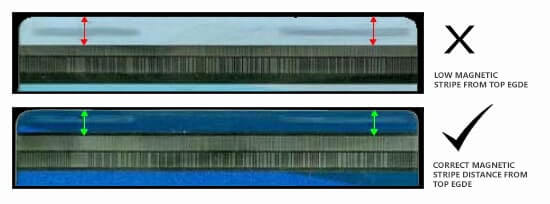

Magstripe Stripe Positioning Problem

- Magstripe positioned too low on card

- Top of Track 1 data chopped off

-

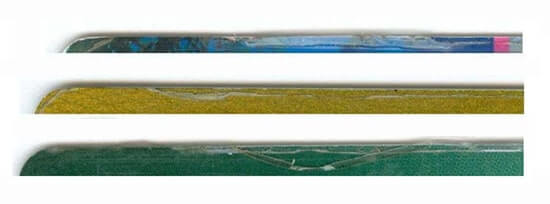

Card Stock Problem affecting Personalisation

- Two chances for CTI to catch this problem

Weak Overlay bond strength

- Devalues brand image

- Can cause chip & magstripe read failure as the card may not align properly with the chip contacts or read head

- Can cause jamming problems in automated card transport mechanisms

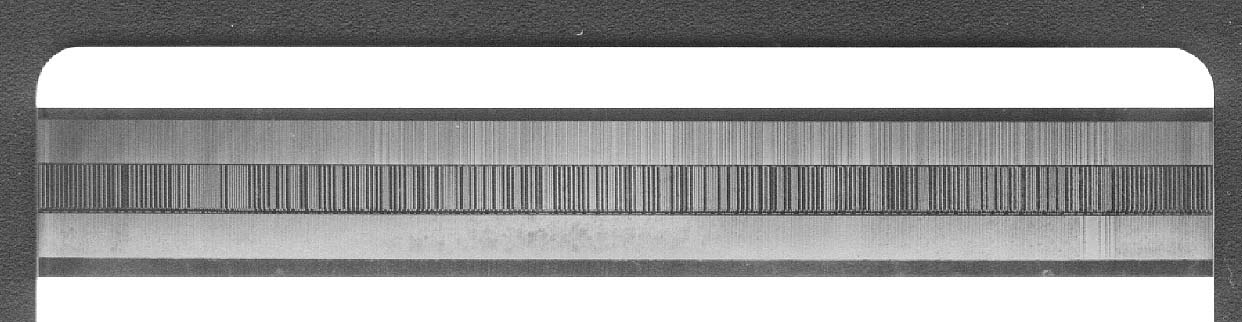

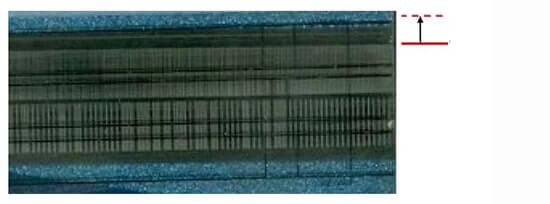

Magstripe Personalisation - Encoded Track Location Problem

- Track Location too low - Red dotted line shows correct position of top of Track 1

- 3/5 Readers CTI tried showed Read Failure

- One Reader tried to read Track 2 and Track 3

- Magstripe Positioning problem also evident