Card Surface Wear

Todays cards encounter surface wear caused by a variety of circumstances; how the cards are stored, the environments the cards are used in, what devices the cards are used in and how frequently they are used in those devices. The major schemes MasterCard, VISA, Amex, JCB, Discover, Unionpay (and many more) recognise this as a serious issue as it affects readability of the Personalised Printing, Magnetic stripe and in some cases, the Contact Integrated Circuit (IC). The physical appearance of cards is also degraded which has an impact on the local branding of the issuing organisation by the card users and the public that they interact with via those cards. CTI offers all of the latest wear and abrasion tests to qualify your cards ability to last its full life in the field.

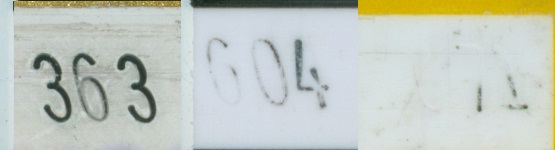

Todays cards encounter surface wear caused by a variety of circumstances; how the cards are stored, the environments the cards are used in, what devices the cards are used in and how frequently they are used in those devices. The major schemes MasterCard, VISA, Amex, JCB, Discover, Unionpay (and many more) recognise this as a serious issue as it affects readability of the Personalised Printing, Magnetic stripe and in some cases, the Contact Integrated Circuit (IC). The physical appearance of cards is also degraded which has an impact on the local branding of the issuing organisation by the card users and the public that they interact with via those cards. CTI offers all of the latest wear and abrasion tests to qualify your cards ability to last its full life in the field.CVV of three different banking cards after 2 years in the field

The issue of card surface wear can affect a multitude of elements on a card, so we will focus on one element instead, the Card Verification Value (CVV – Also referred to as a Card Verification Code). This is the short number printed on the back of credit cards required by many online/www retailers for customer purchases, and as such are vitally important in todays retail environment. The personalisation process often indent-prints the CVV number into the card, but may also be laser engraved or printed in some cases. MasterCard recommends that the impression be sufficient enough that the outline of the characters will be perceivable, but not easily legible, on the front of the card*. By doing this the effect of wear on the CVV number will be lessened as the digits will be slightly lower than the surrounding card surface. Other methods use heat to bond or change the surface of the card sufficiently that the text will stand the test of time. All of these methods aim to be both secure and durable, but how do you know the durability of your cards will be sufficient without performing the necessary testing?

CTI offers testing for card surface wear in which we can check the resistance to wear of your cards CVV as well as other elements such as Signature Panels, Holograms, Personalised Photographs/Characters, Bar Codes, Magnetic Stripes, IC Chips, and any number of other aspects that are susceptible. The ISO/IEC 24789-1 provides an abrasion test method for exactly this purpose. CTI can also perform the MasterCard Card Quality Management and ANSI INCITS 322 test methods which include, but not limited to the Sandpaper Rub, Soft Eraser Rub and Tape Pull tests. So if you need to be assured that your cards are built and personalised to withstand their expected life cycles, then please contact CTI today about developing a testing plan for your cards.

*Reference: MC CQM v2.16 Section 14.1.3.1